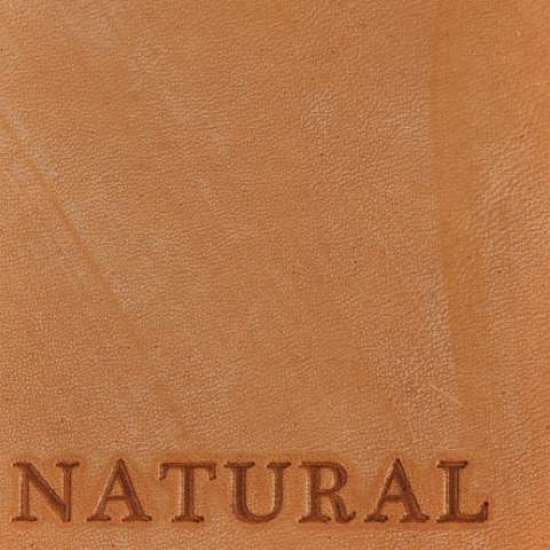

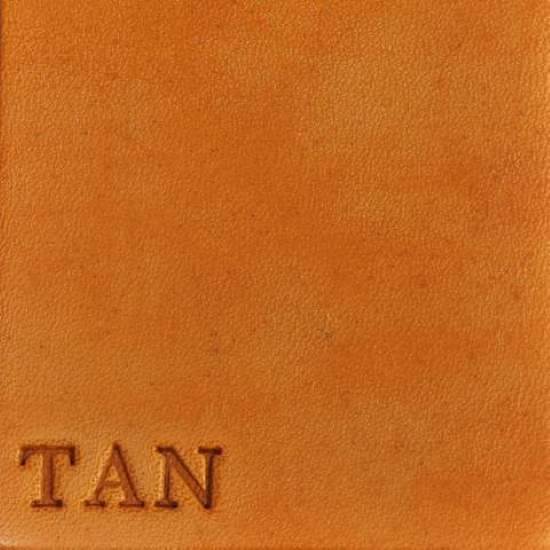

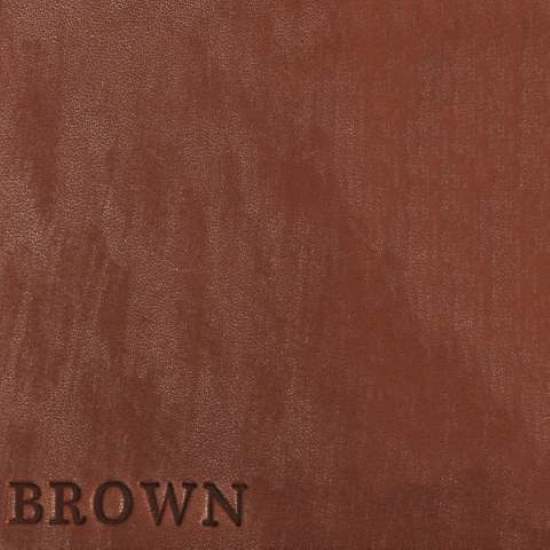

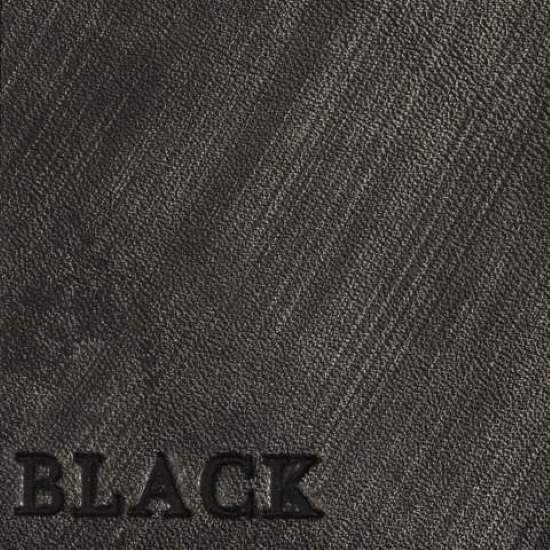

For leather furniture upholstery we use Crest JMT Leather. Crest JMT Leather blends centuries old Italian craftsmanship with pioneering technology for high-end use in all areas of upholstery. Durable, supple, comfortable and the finest quality. As a natural product, leather will often display traces of its origins - differing fibre density, lines, textures, tones and marks. These hallmarks are not a detraction but a reminder of its natural beauty.

For fabric upholstery it is Camira. We tend to make use of Camira Fabrics Main Line Flax range for a few reasons. Firstly, its resemblance to the mid-century Scandinavian weave fabrics we love. Its combination of spun pure flax and wool blend that creates a beautiful mix of texture and large selection of colours. Also, its inherent flame resistance and heavy-duty wear.

The woods we use for bespoke furniture are of the finest quality and suitability for each project. All timbers are carefully chosen from trusted and selected sustainable timber suppliers with up-to-date ethics.

- Sustainable - Selected - Premium

- Camira Main Line Flax

- Upholstery Leather - Crest JMT

For our traditionally hand stitched leather work on storage boxes and 20th Century 'slung' leather chairs etc we utilise the very finest oak bark tanned bridle leather from only remaining traditional oak bark tannery in Britain - producing some of the finest pit tanned leather in the world, with a reputation to match. Leather has been produced on this same site since the Roman times but has been family owned for over 150 years since 1862. It has been passed through five generations of tanners along with the unique techniques and methods used to create their unrivalled, hardwearing and strong leather.

Oak bark tannage is a long, gentle process that protects the natural fibres of the hide unlike modern tanning methods. We choose the best local hides and treat them in a sustainable process using natural products. It takes 14 months to produce each piece of leather. The full grain hides we use may have scarring, stretch marks and other natural characteristics giving a true representation of what leather should look like. This will age and the patina will change with time - giving that already authentic piece the individual character that only truly natural materials and craftsmanship can.